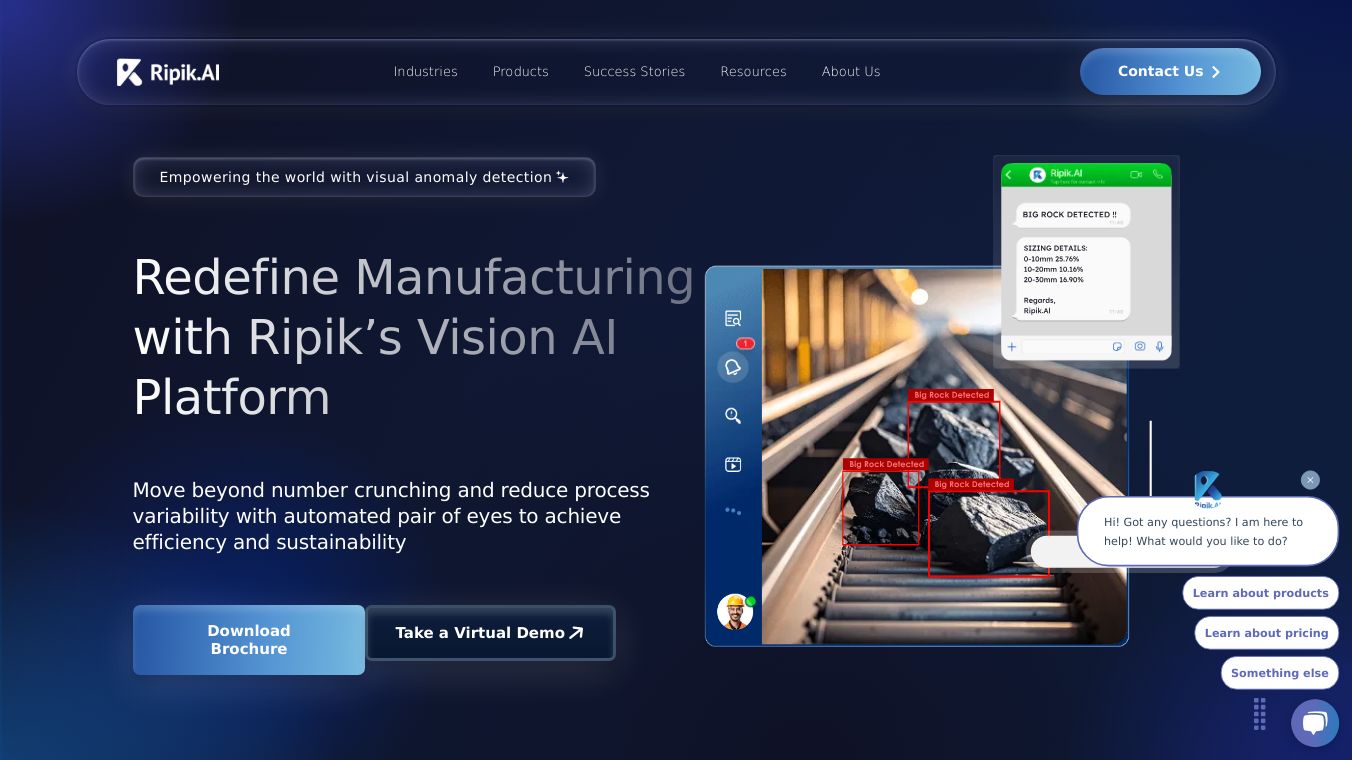

Ripik AI

What is Ripik AI?

Ripik AI is an Applied AI company that develops computer vision agents designed to serve as an automated pair of eyes for industries like steel, cement, and chemicals. These AI-driven agents provide 24/7 monitoring with over 95% accuracy, enabling real-time decision-making and eliminating human error and inefficiencies. Ripik AI's solutions cover material, process, and equipment monitoring, driving higher throughput, improved energy efficiency, and enhanced quality across industrial operations.

Benefits

Ripik AI offers several key benefits for industrial operations:

- 24/7 Monitoring: Ripik AI agents provide continuous monitoring, ensuring that operations run smoothly around the clock.

- High Accuracy: With over 95% accuracy, these agents detect anomalies and provide real-time alerts, reducing the likelihood of errors and inefficiencies.

- Real-Time Decision Making: The agents enable immediate decision-making, allowing for quick responses to issues and optimizing process control.

- Scalability: The Ripik Vision Platform allows for the deployment of hundreds of Vision AI agents with a single click, ensuring seamless scale and rapid deployment.

- User-Friendly Interface: The platform is supported by a robust back-end and an extremely user-friendly UI, driving accuracy, efficacy, and adoption.

Use Cases

Ripik AI's Vision AI agents can be applied in various industrial settings, including:

- Steel Industry: Monitoring ladle activities, DRI, HBI, and coke size and moisture, and ensuring SOP compliances.

- Cement Industry: Monitoring conveyor belt operations, SOP compliances, and workforce activities.

- Chemical Industry: Monitoring anode surface, switchyard hotspots, and tamped metal SOP compliances.

- Energy Industry: Monitoring coal size and moisture, boiler fuel leakage, and refractory conditions.

- Pharmaceutical Industry: Optimizing scheduling processes and capturing on-ground realities through data.

Vibes

Ripik AI has been trusted by leading global enterprises and has received positive testimonials from clients across various industries. Some notable testimonials include:

- Sr. Vice President, Head Ferro Alloy Business Unit: Ripik.ai has been associated with IMFA since January 2023 towards the implementation of Industry 4.0 in their Choudwar plant. The team has demonstrated good knowledge in data science and machine learning, with high problem-solving skills.

- Head Technology and Projects Electrical Maintenance, Tata Steel Limited: The Ripik.ai team played a crucial role in the Advanced Analytics program in TSK between 2017 and 2020, working on various use cases across Blast Furnace, Sinter Plant, and Steel Melt Shop.

- Chief Digital Officer, Godrej: Ripik.ai has been the analytics partner of Godrej & Boyce since March 2022, working on projects with the Interio and Aerospace businesses and exploring use cases for other businesses.

- Chief Digital Officer, ESL Steel Limited: Ripik.ai has been working on three use cases in the Upstream section at the Bokaro plant, including Digital Twin of Blast Furnace, Burden Mix optimization in Blast Furnace, and Green Mix optimization in Sinter Plant.

- Chief of Mechanical Maintenance, Tata Steel Limited: Ripik.ai has been implementing a Digital AI-based Maintenance Operating System at the Kalinganagar facility since November 2022, working on modules like Digitization of Stores and Spares Inventory Management and Digital Workforce Management for Maintenance Activities.

- AVP, MBB, Pulp Business: Ripik.ai has completed three machine learning/data science use cases in the Harihar plant and one use case in the Kharach plant, demonstrating exceptional problem-solving skills and expertise in data science.

- Chief Digital Officer, Godrej and Boyce Manufacturing Company: Ripik.ai has been the analytics partner to Godrej & Boyce Mfg. Ltd. since March 2022, working on projects with the Interio and Aerospace businesses and exploring use cases for other businesses.

- Senior Advisor, IPA: Ripik Optimus can change the complex scheduling process in the Pharma industry, capturing several on-ground realities through the right set of data.

- Former CEO, Glenmark: Ripik Optimus handles all Pharma constraints and helps in capturing several on-ground realities through the right set of data.

- Digital Transformation Technology Lead, Holcim: The software is easy to use and well-designed, with the Ripik team providing excellent service and addressing all questions and problems during the implementation and testing phase.

Additional Information

Ripik AI has a proven track record of driving customer success across various industries. Some notable success stories include:

- Ladle Activity Tracker: Enhanced ladle operations in steel plants with comprehensive real-time monitoring.

- Material Sizing Solution: Achieved 95% accuracy in raw material monitoring.

- Volumetric Estimation using LIDAR: Transformed stockpile management, achieving over 95% accuracy.

- Fuel Rate and Throughput Improvement: Improved fuel rate and throughput in a cost-competitive steel market.

- Real-Time Asset Monitoring: Transformed a leading EPC company's operations with real-time asset monitoring.

- Conveyor Belt Monitoring: Achieved a 70% reduction in downtime of conveyor failures.

- Refractory Monitoring: Reduced unplanned downtime by detecting early signs of refractory damage.

- AFR Monitoring: Reduced inconsistencies in calorific values, optimizing combustion efficiency.

- Crusher Blockages: Achieved an 82% reduction in crusher blockages and a 20% decrease in unwanted stoppages in cement crushers.

- Flare Stack Monitoring System: Delivered over 90% measurement accuracy, replacing manual judgment.

Ripik AI's Vision AI solutions are transforming operations across the industrial landscape, driving real-time insights, enhanced safety, and intelligent process optimizations.

This content is either user submitted or generated using AI technology (including, but not limited to, Google Gemini API, Llama, Grok, and Mistral), based on automated research and analysis of public data sources from search engines like DuckDuckGo, Google Search, and SearXNG, and directly from the tool's own website and with minimal to no human editing/review. THEJO AI is not affiliated with or endorsed by the AI tools or services mentioned. This is provided for informational and reference purposes only, is not an endorsement or official advice, and may contain inaccuracies or biases. Please verify details with original sources.

Comments

Please log in to post a comment.